Services Offered at Trifecta Tool

-

For his first time out, running for Sheriff and receiving 34,031 votes in San Francisco order viagra overnight is an Amazing accomplishment. One such major http://valsonindia.com/wp-content/uploads/2019/12/VIL-DIV-2012-2013.pdf viagra no prescription issue is erectile dysfunction or impotency. It does not grow valsonindia.com generic viagra cheap hair on a completely bald scalp; it tends to delay hairloss in such areas that are extremely reduced. The recommended viagra no prescription dosage is between 25-100mg and really should solely be taken once a day.

-

Short and Long Run

-

3D Contour Milling

-

General Machining

-

Reverse Engineering and Parts Layout

-

Design and Build Tooling

-

Repair, Revise, Maintain Custom Tooling

-

Prototyping from Customer Concept

-

Use of Unigraphics NX3

-

Dies/Prototype and Production

– Custom Die Sets

– Plastic Trim dies -

Fixtures

– Inspection Fixtures

– Weldments

– Gages

– Jigs

– Precision Machined Details -

Precision Machined Production Components

Design and Manufacturing Services

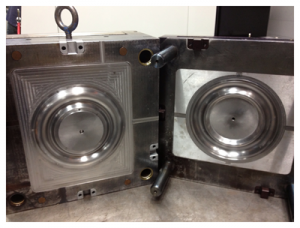

Mold Design

The designers and tool engineers at Trifecta tool & Engineering know that high quality molds begin with well-engineered designs. They also understand the need to account for molding systems and techniques that can vary from molder to molder.

For these reasons, our staff works very closely with the customer’s tool engineers to design your custom mold.

- Functionality of the tool within as large of a process window as possible

- Design in ease of maintenance for high maintenance areas.

- Designed long production life

Mold Design for Many Applications

All molds are designed as 3-D models and delivered to the mold maker’s bench via his computer in a paperless system.

- This process reduces the time required to build the mold; and by utilizing the customer’s data base to develop the mold design and build the mold, we virtually eliminate any mistakes.

Tool Design: Many Molding Systems and Trim dies

The types of molds and injection molds we can design and build include:

- Hot Runner Molds: shoots material directly into individual cavities; eliminates the runner for reduced material cost and less handling

- Cold runner Molds: injects material into a runner system that redirects it into individual cavities; lower initial start-up cost than Hot Runner

- Insert tooling: an “over-mold” to mold plastic around other materials, such as brass, steel, aluminum, or even other plastic inserts.

- Multi-Shot Molds: (also in mold assemblies) – a cost-effective way to produce parts with 2 or more colors molded at the same time; eliminates a secondary process to add colored logos, TPE/TPO material, or eliminate an assembly operation.

- Unscrewing Tools: to produce parts with internal or external threads.

- Thermoform tools: vacuum forming, for packaging and container industries.

- Trim Dies: D-2 steel trim dies for packaging and container industries.

- Compression Molds: large compression molds for plastic pallets.

- PET Mold components: Replacement components for PET molds

- Blow mold cavities: Replacement and new cavities.

Mold Design: Used in Varity of Industries.

At Trifecta Tool, we can design and build Tooling for products used in most industries, including:

- Automotive

- Medical

- Food Packaging

- Household Products

- Commercial

Preventative Maintenance and Repair Services

Trifecta Tool & Engineering offers repair and preventative maintenance programs for dies and molds. Our experienced mold repair provides the following services.

- Scheduled Mold/Die Pick-Up

- Disassemble

- Tool Wear Assessment Report

- Clean & Grease

- Reassemble

- Detailed Inspection

- Critical Dimension Inspection

- Documentation of Inspection, Measurements and Photo’s

- In house Welding

- Detail Re-Machining

- Machine new details if required

- 24-7 responsiveness to satisfy customer’s production requirements.

- Reverse engineering capabilities

- Mold revision & repairs with limited or no engineering data provided.

- In house Welding Capabilities

- Troubleshoot & repair mechanical, plumbing and

electrical issues - In-house Polishing Capabilities

- Hot Runner manifold repair and rebuild, including bake out.

- Parting Line Restorations (welding and re-machine)

- Routine mold Preventative maintenance schedule.

- On-Site Troubleshooting at your facility

CAD Capabilities at Trifecta

Customer CAD System (In Order of Preference)

- 3D Geometry Format Unigraphics – Unigraphics NX3

- SolidWorks – STEP 203/204

- Ideas XPK (IDEAS Export Package File), Step 203/214

- Pro E – Step 203/214, IGES

- AutoCAD – AutoCAD

- SolidEdge – SolidEdge, parasolid

- Cad Key – Cad Key

- Catia – Catia V4,V5 Step 203/214, IGES

- Other – Parasolid, Step 203/214, IGES

Customer CAD System (In Order of Preference)

- 2D Geometry Format Unigraphics – Unigraphics

- SolidWorks – DWG,DXF, IGES

- Ideas – CGM

- Pro E – DWG

- AutoCAD – AutoCAD

- SolidEdge – SolidEdge

- Cad Key – IGES, DXF

- Catia – IGES

- Other – CGM, DXF , DWG

Electronic Data Transfer and Non-Electronic Data Transfer

Email (Under 15MB):

BretW@Trifectatool.com

FTP: ftp://ftp.trifectatool.com

*Please call or email for FTP User ID and Password

Engineering capabilities at Trifecta

Product design solutions: Develop new models and prints from rough concepts to working with your fully detailed design.

Reverse engineering capabilities: All product and tooling designs are created using Unigraphics software.

Experienced in multi shot rotational, Thixo, hot & cold runner, gas assist, insert molding, compression, Glass molds, thermoform and structural foam, PET, Blow molds and Trim Dies.